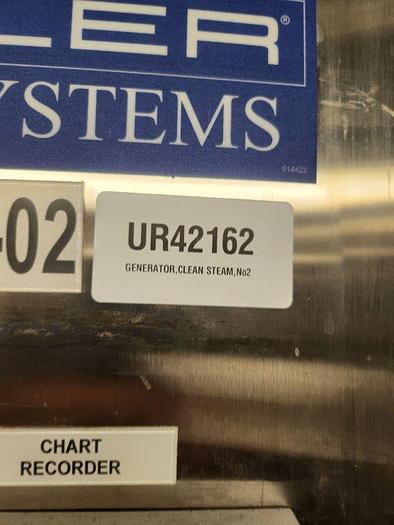

2014 Mueller PyroPure P7310 Pure Steam Generator

2014 Mueller PyroPure P7310 Pure Steam Generator

£35,000 (GBP)

Location:Duxford, United Kingdom

Available quantity:2

Description

This listing is for 1 of 2 Mueller PyroPure P7310 Pure Steam Generator.

The unit is in full working condition and is ready for immediate release.

This Unit was installed new in 2015 by Freestead Process Technology.

The “Turned on Time”of the unit is 65,000 hours, but as this unit is 1 of 2 generators in an alternating system it does not indicate the "Steam Production Time". The sites steam requirements were low therefore the unit is in immaculate condition.

They have full maintenance records backed up on their electronic technical system supplied as an extra by Freestead.

This Unit is fitted with a Allen Bradley Compact Logix PLC and Panel View plus 1000 HMI's

The Unit is supplied with-

⦁ Feed water pump system

⦁ Pure steam condensate sampling system

⦁ Pure steam analyser

⦁ Stainless steel sheathing and frame

⦁ Feed water analyser

⦁ Degasser

The Mueller PyroPure P7310 Pure Steam Generator is a high-performance system designed to produce pyrogen-free pure steam suitable for the most demanding applications, such as pharmaceutical production, biotechnology processes, and healthcare sterilization. Built to meet or exceed U.S. Pharmacopoeia (USP) standards, the P7310 combines precision engineering, advanced technology, and robust materials to ensure consistent performance and reliability. They are CE marked and compliant with 3.1B material certification.

The terms pure steam and clean steam are often used interchangeably in the pharmaceutical industry. However, not all equipment marketed as clean steam generators are up to the task of producing WFI quality pharmaceutical pure steam. Mueller pure steam generators use a tangential nozzle to provide separation of impurities from incoming feed water, producing pyrogen-free steam that, when condensed, meets USP requirements for water for injection.

Key Benefits

Superior Steam Quality:

Produces pyrogen-free steam that meets USP requirements, ensuring safety and regulatory compliance.

Optimized for critical applications like autoclaves, clean room humidification, and steam-in-place (SIP) sterilization.

Achieves a 5 Log reduction in contaminants, which corresponds to a 99.999% reduction in microbial populations. This level of reduction ensures the highest degree of sterilization, making it ideal for pharmaceutical and biotechnology applications where absolute purity is critical.

Efficient Design:

External evaporator allows easy access for inspection and maintenance, reducing downtime.

Separation column has no internal components requiring maintenance, eliminating potential for bacterial growth.

Efficient heat transfer with a double-tube sheet evaporator minimizes stress cracking and maximizes performance.

Ease of Maintenance:

All critical components can be serviced with only 24" of clearance around the system.

Fully drainable design prevents standing water, reducing contamination risks.

Polished 316/316L stainless steel construction ensures durability and easy cleaning.

Enhanced Operational Features:

Minimal instrumentation is required, reducing complexity and operational costs.

Simplified control with an Allen-Bradley PLC system, compatible with Ethernet for integration with facility systems.

Certified elastomers (USP Class VI) provide enhanced compatibility with feed water and product.

Specifications

Performance:

Pure Steam Capacity: from 0 to 700 kg/hr at optimal feed water conditions.

Operating Pressure Range: Pure steam output pressure up to 50 psig.

Material and Surface Finish:

Product-contact surfaces: Electro-polished 316/316L stainless steel with a maximum roughness of 20 Ra.

Feed water-contact surfaces: Polished to 25 Ra maximum for longevity and cleanliness.

Connections:

Feed water Inlet: 1" Tri-Clamp.

Pure Steam Outlet: 2" Tri-Clamp.

Condensate Outlet: 1" FNPT.

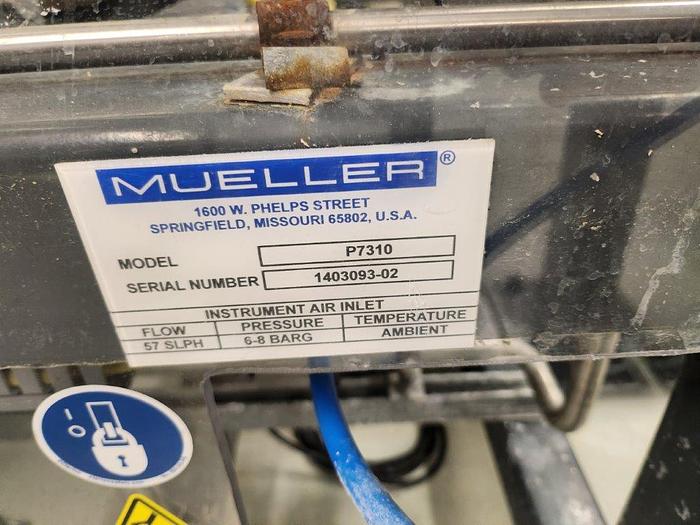

Instrument Air: 0.25" FNPT.

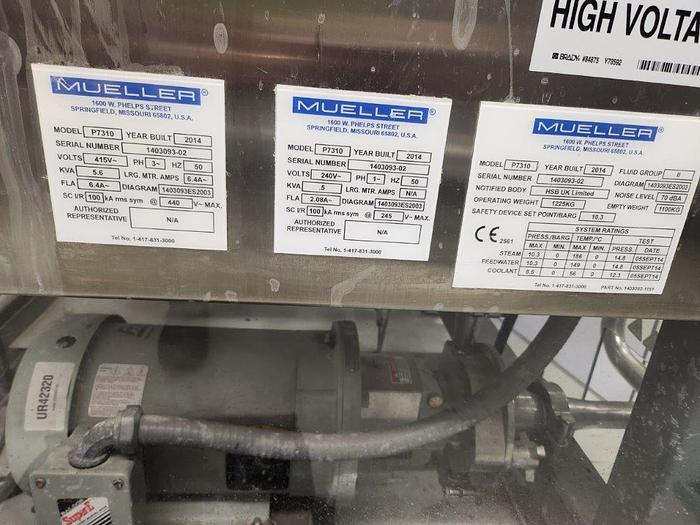

Power Requirements:

460 VAC, 3-phase, 60 Hz (customisable options available).

Dimensions and Weight:

Height: 115" (292 cm)

Width: 50" (127 cm)

Depth: 54.5" (138 cm)

Approximate Operating Weight: 2,350 lbs (1,070 kg).

Feed water Requirements:

Inlet temperature: 70°F (21°C) recommended.

Maximum silica: 1 ppm.

Free from chlorine, chlorides, or amines.

Flow rate must exceed pure steam production by 5–10% to accommodate blow down.

Optional Features:

Feed water Pump System: Boosts feed water pressure for systems with lower supply pressure.

Pure Steam Condensate Sampling System: Simplifies sampling for compliance and quality testing.

Pure Steam Analyser: Monitors and records temperature and conductivity, triggering alarms if thresholds are exceeded.

Degasser: Removes non-condensable gases to meet strict purity standards.

Water-for-Injection (WFI) Production: Integrates a pure steam condenser to produce up to 150 gallons/hour of WFI.

Applications:

Pharmaceutical Manufacturing: Sterilization of equipment, tools, and containers.

Biotechnology: Ensures sterile conditions for sensitive biological processes.

Healthcare: Critical area humidification and sterilization in hospitals and clinics.

Food and Beverage: Clean steam for production and packaging processes.

Specifications

| Manufacturer | Mueller |

| Model | PyroPure P7310 |

| Year | 2014 |

| Condition | Used |

| Stock Number | 413024 |