2014 Mueller PyroPure WFI System

2014 Mueller PyroPure WFI System

£150,000 (GBP)

Location:Duxford, United Kingdom

Available quantity:1

Description

This listing is for a Full Mueller PyroPue WFI System.

The unit is in full working condition and is ready for immediate release.

This Unit was installed new in 2015 by Freestead Process Technology.

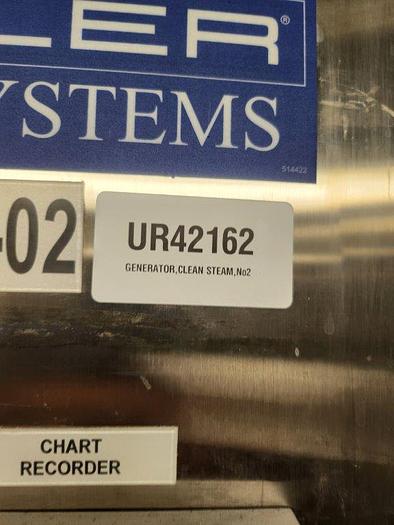

This system is in immaculate condition as the sites steam requirements were low.The “Turned on Time”of the Steam Generator's is 65,000 hours, but as this unit is 1 of 2 generators in an alternating system it does not indicate the "Steam Production Time".

The Mueller PyroPure WFI System stands out as a high-performance, integrated solution for the pharmaceutical and biotechnology industries, focusing on the production, storage, and distribution of ultra-high-purity Water for Injection (WFI). Below is an in-depth look at its components, capabilities, and specifications.

Key Components

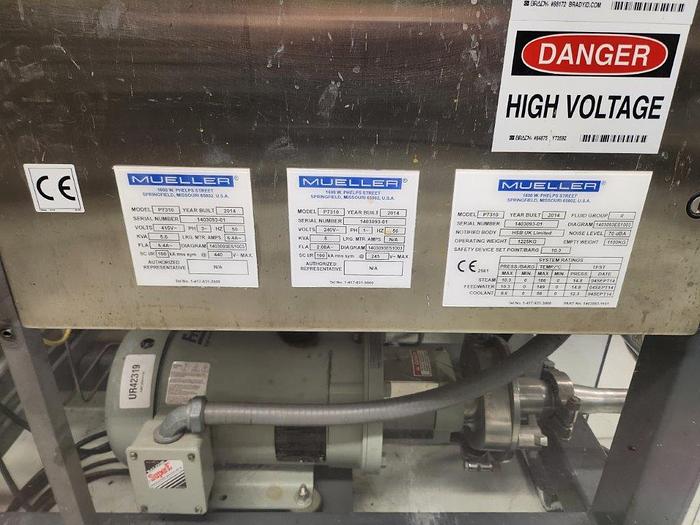

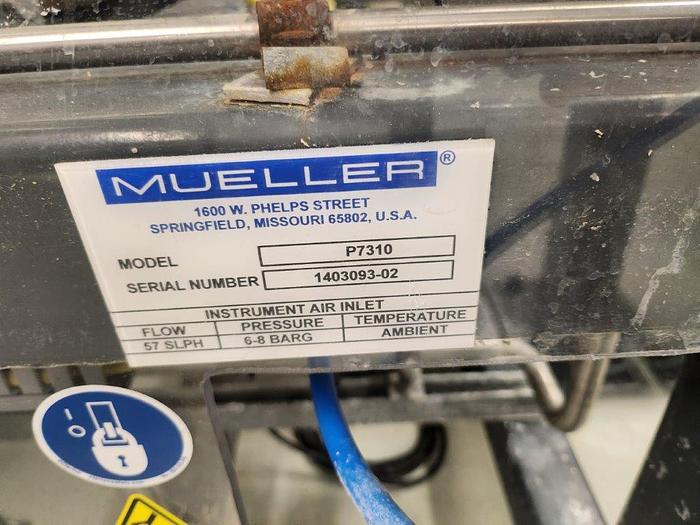

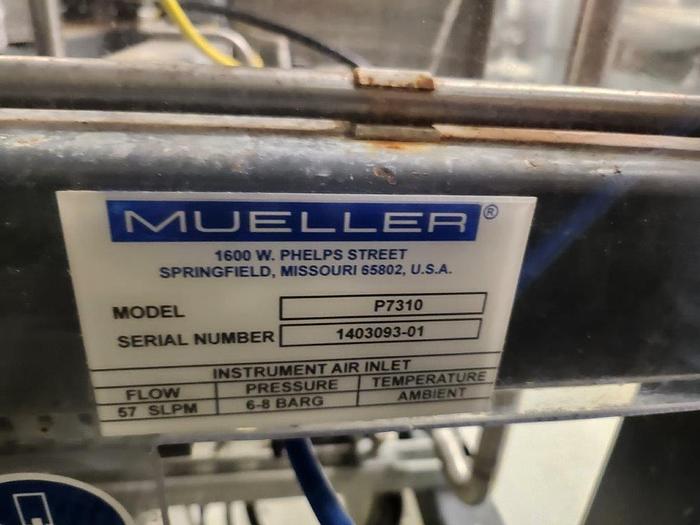

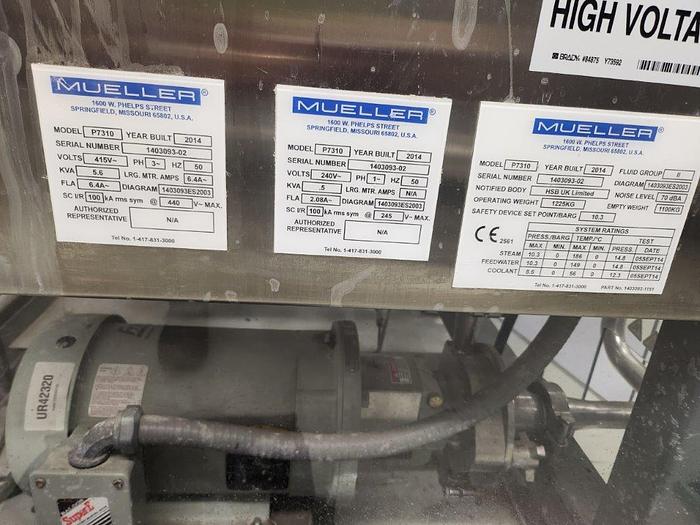

2x Mueller P7310 Pure Steam Generator

High Capacity: Generates from 0 to 700 kg/hr of pure steam, suitable for high-volume operations.

Operational Flexibility: Can operate alternately with another unit of the same model, maximizing efficiency and reducing downtime.

Regulatory Compliance: Meets USP WFI standards, ensuring suitability for pharmaceutical applications.

Maintenance-Friendly Design: Features an external evaporator for easy access and servicing, minimizing contamination risks.

Advanced Control: Equipped with an Allen Bradley Compact Logix PLC and an intuitive operator interface terminal (OIT) for real-time monitoring and control.

Safety Mechanisms: Includes pressure relief valves and temperature controls to ensure safe operation.

Energy Efficiency: Designed to optimize energy consumption, especially when alternating operations between units.

Durable Construction: Made from high-quality stainless steel for longevity and hygienic conditions.

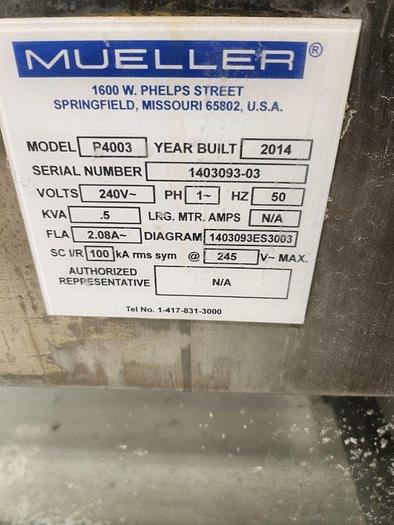

1x Mueller P4003 Pure Steam Condensing System

Condition: This unit is in full working condition and ready for immediate release. Installed new in 2015 by Freestead Process Technology.

Capacity: Produces 100 gallons per hour (379 litres per hour) of WFI-quality distillate, with a pure steam inlet capacity of 807 lb/hr (366 kg/hr).

Compliance: Meets stringent USP WFI standards, is CE marked, and FDA compliant with 3.1B material certification.

Core Features:

Utilizes a tangential nozzle design for superior impurity separation.

Drainable components to minimize contamination risks, with electro-polished 316/316L stainless steel ensuring hygienic operation.

Easy maintenance due to a removable tube bundle in the condenser and minimal instrumentation, requiring just 24 inches of clearance for service.

1x Ormandy Newade WFI Storage Vessel

Condition: This 2000L WFI storage vessel is also in full working condition, installed in 2015 by Freestead Process Technology.

Capacity: Perfectly balances storage efficiency for mid-sized operations with its 2000 litres capacity.

Design Flexibility: Available in both horizontal and vertical configurations, customisable based on specific facility layouts.

Material Excellence: Made from high-grade austenitic and Duplex stainless steel, ensuring durability and resistance to corrosion.

Compliance: Adheres to key industry standards such as PD5500, ASME VIII, and EN 13445, and is CE marked under the Pressure Equipment Directive.

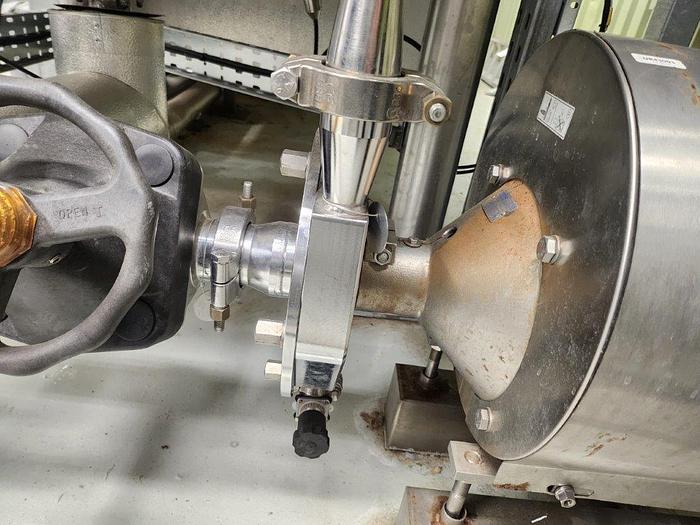

1x Fristam FPE742/185A Centrifugal Pump

Condition: This robust 5.5KW sanitary pump is operational and ready for immediate use, also installed in 2015 by Freestead Process Technology.

Hygienic Design: Features close internal clearances (as tight as 0.5 mm) for efficient and sanitary operation, especially in high-purity applications.

Advanced Engineering: Optimized impeller design reduces risks of cavitation, enhancing the smooth transfer of sensitive products.

Robust Construction: Crafted from 316L stainless steel, known for its strength and durability, making it suitable for demanding environments.

Applications:

Pharmaceutical Manufacturing: Ideal for sterilizing environments, sensitive product handling, and ensuring compliance with stringent regulations.

Biotechnology: Provides essential WFI for bio-processing, maintaining the integrity of sensitive biological applications.

Healthcare: Supports humidification and sterilization processes in clean rooms and hospital settings.

1x Freestead Technology WFI Storage Vessel Control panel

A control panel designed and built for the WFI system.

Please see our individual product listing of each item for more detailed information.

Specifications

| Manufacturer | Mueller |

| Model | PyroPure |

| Year | 2014 |

| Condition | Used |

| Stock Number | 413024 |